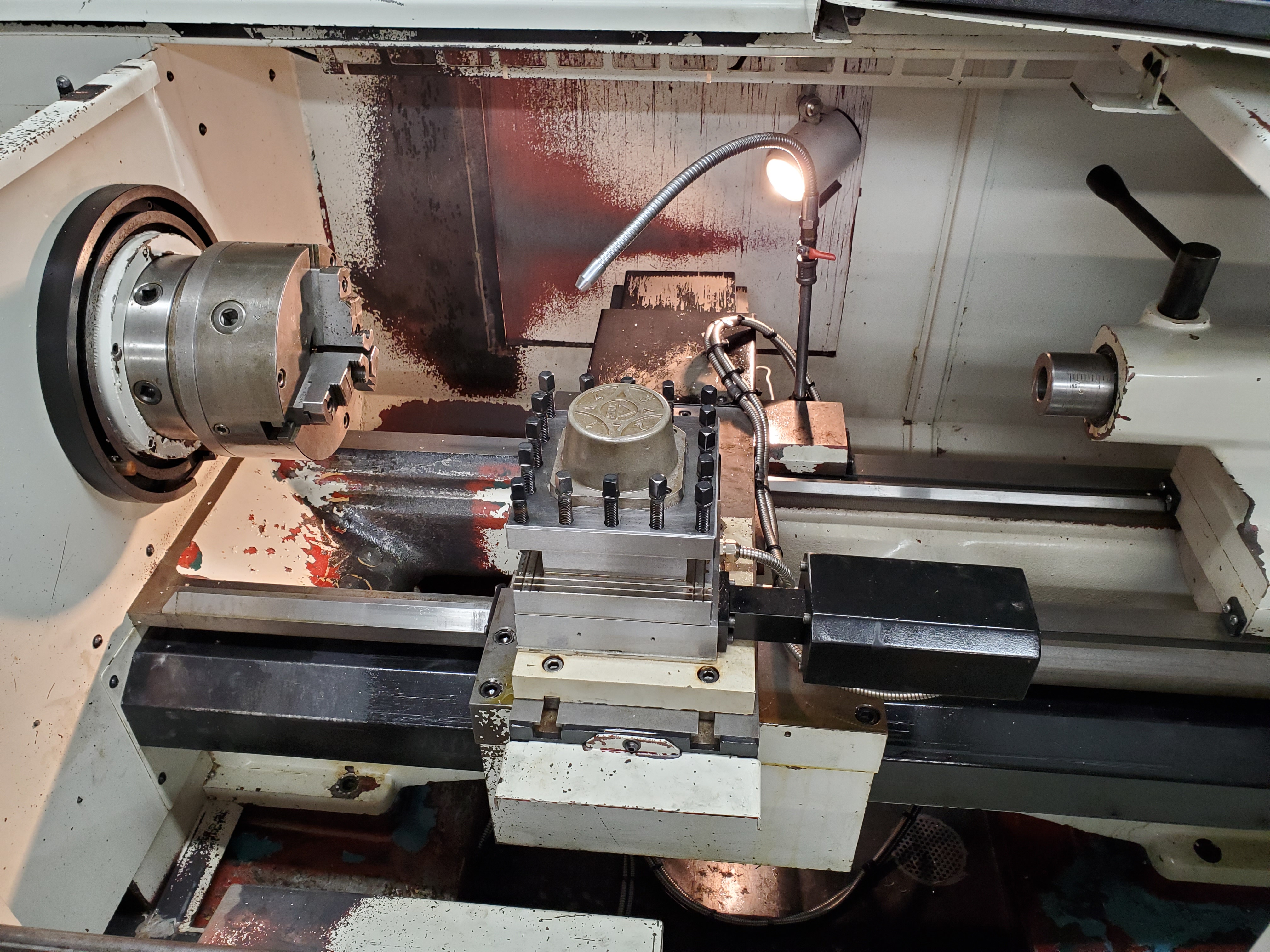

1630SX Southwestern Industries Proto Trak Lathe with Programmable Tool Changer

For Sale Southwestern Industries Proto Trak 1630SX Lathe with Programmable Tool Changer

· Height of Centers-8”

· Distance between centers-30”

· Swing over bed -16”

· Swing over saddle wings-16”

· Swing over cross slide-8.6”

· Cross slide travel-9.6”

· Tool section max-3 /4”

· Coolant tank capacity-11 gal.

· Width of Bed-12.6”

· Height of Bed-12.6”

· Spindle Nose (Camlock)-D1-6

· Spindle through hole-2.12”

· Spindle taper-MT#6

· Taper in reduction sleeve -N/A

· Spindle dia at front bearing-3.15”

· Number of bearings-2

· Bearing class (radial round)-P5

· Spindle speed range (RPM)-150-2500

· Optional Tailstock Quill travel-5”

– Quill diameter-2.36”

– Quill taper hole-MT#4

· Spindle Motor HP -7.5

· Power requirements, control-110V; 1P; 8 A

· Power requirements, machine-220V;3P;60Hz

· Amps full load current-25

· Dimensions net – 79 x 38 x 54”

· Dimensions shipping – 87 x 45 x 67”

· Weight net – 3,200 lbs.

· Maximum rapid feed X – 100

· Maximum rapid feed Z – 150

· Spindle motor brake – Dynamic braking

· Way surface hardness – 400 – 450 HB

· Head stock lubrication – Oil bath

· Sliding door for easy set-ups

· Bedways hardened and ground

· Sliding surfaces Turcite coated

· Dovetails on cross slide, V-ways on saddle

· Adjustable saddle gibs

ProtoTRAK SLX System Specifications

(O) indicates optional feature

ProtoTRAK System Hardware

· ProtoTRAK SLX CNC

· Two-axis CNC, two-axis DRO

· Electronic handwheels for manual operation

· 10.4” color active-matrix screen

· Industrial-grade Celeron® processor

· 128 Mb Ram

· P/S 2 Keyboard connector

· 2 USB connectors

· Override of program feedrate

· Override of program spindle speed

· LED status lights built into display

· TEAC floppy drive

· Gasket-sealed enclosures

· Jogstick for convenient jog

· Clean front panel with few hard keys

Software Features – General Operation

· Clear, uncluttered screen display

· Prompted data inputs

· English language – no codes

· Soft keys – change within context

· Windows® operating system

· Color graphics with adjustable views

· Inch/mm selectable

· Convenient modes of operation (see below)

DRO Mode features

· Incremental and absolute dimensions

· Jog at rapid with override

· Powerfeed X or Z

· Tapers of any angle

· Radius

· Fillet

· Go To dimensions (O)

· Servo motor return to Home

· Spindle speed setting with override

· Tool offsets from library

· Fine/course handwheel resolution for traking option (O)

Program Mode features

· Geometry-based programming

· Event comments (O)

· Incremental and absolute dimensions

· Automatic tool nose radius compensation

· Circular interpolation

· Linear interpolation

· Look –graphics with a single button push

· List step – graphics with programmed events displayed

· Alphanumeric program names

· Conrad – one input for automatic corner radius programming

· Chamfer – one input for automatic chamfer programming

· Math helps with graphical interface

· Auto load of math solutions

· Subroutine repeat of programmed events

· Nesting

· Programmable spindle speeds

· Program run time clock in Run Mode (O)

· CSS (Constant Surface Speed) programming (O)

· IPR (Inch per Revolution) programming (O)

· Gang tooling (O)

Canned cycles

· Position

· Drill

· Bore

· Turn

· Arc

· Cycle

· Thread

· Groove

· Custom thread (O)

· Tap (O)

Edit mode Features

· Delete events

· Erase program

· Spreadsheet editing (O)

· Global data change (O)

· Clipboard to copy events between programs (O)

Set Up Mode Features

· Program diagnostics

· Advanced tool library

· Tool library file save

· Icon-prompted tool setting

· Tool offsets with modifiers

· Single tool set-up

· Indexer tool set-up (O)

· Advanced diagnostic routines

· Software travel limits

· Tool path graphics with adjustable views

· Program run time estimation clock

Run Mode Features

· CAM file program run

· Real time run graphics with tool icon

· Countdown clock to next pause or tool change (O)

· TRAKing of programs during program run (O)

· Automatic indexing for tool change (O)

· Gang tool operation (O)

Program In/Out Mode Features

· Simple program storage to floppy

· CAM program converter

· Converter for prior-generation ProtoTRAK programs

· Selection of file storage locations (O)

· Automatic file back-up routine (O)

· Preview graphics for unopened files (O)